Reverse Engineering

Reverse Engineering - aplication

- production replicas of tools where the customer does not have CAD data

- repair tools

- Data model for further processing in CAD, CAM, CAE

Technical Specification Reverse Engineering

- 3D model accuracy to + - 0.05 mm from the source *. stl 3D scanning

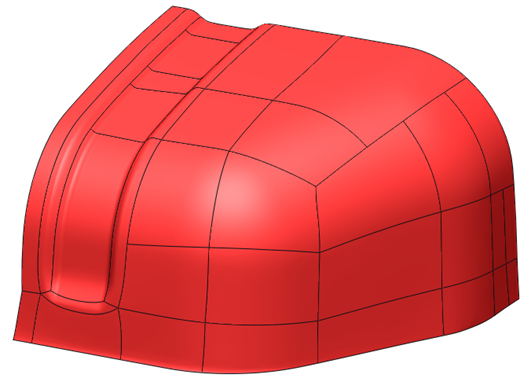

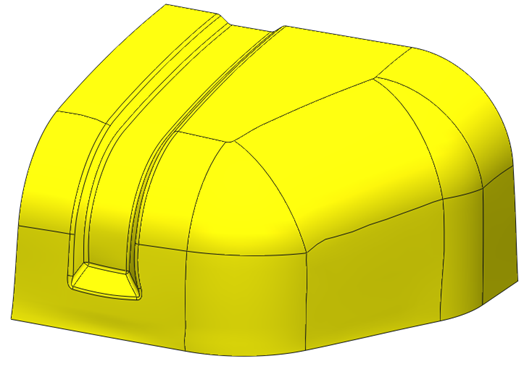

- choice of output between CAD model NURBS / PARAMETRIC

- output formats: *. iges, *. step, *. parasolid

|

NURBS

|

PARAMETRIC

|

|

|

|

Reverse Engineering

V případě zájmu o Reverse Engineering nás neváhejte kontaktovat prostřednictvím tohoto formuláře.