Metal Prototypes - 3D print

DMLS - Direct Metal Laser Sintering is an aditive technology that works by sintering very fine layers of metal powders layer-bylayer from the bottom up until build is complete.

Technical Specification - Laser Sintering

- technology: DMLS - Direct Metal Laser Sintering

- machine: EOSINT M270

- workspace: 250x250x215 mm

- layer thickness: 0,02 / 0,04 mm

- 3D data input format: *.stl

- choice of 3 materials

DMLS materials available

- MS1 - Maraging steel (1.2709) - serial plastics molds, serial parts, functional metal prototypes

- SS - Stainless Steel (1.4542) - serial parts, functional metal prototypes

- DM20 - Bronze - prototype plastics molds, functional metal prototypes

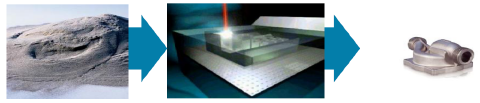

Direct Metal Laser Sintering process

Direct Metal Laser Sintering (DMLS) is a generative technology which creates product in individual layers. Thus it is possible to build very fast and effectively any geometric shape without cutting. 3D CAD model of product is necessary. DMLS builds product by layers according the 3D CAD model. Laser melts metal powder just in area of product. Product of DMLS is fully functional and homogenous metal part.

|

|

Metal Prototypes - 3D print

If interested in Metal Prototypes - 3D print, please contact us through this form.